Heat-resistant alloys are an essential component of many industrial and commercial processes. These alloys are used in the aerospace industry, petrochemical manufacturing, and power engineering, where they are exposed to extreme temperatures and harsh chemical environments. The durability and reliability of these materials determine the safety and efficiency of the final product, making them a critical component of the modern economy.

Specialists from Belgorod State University (BelSU) have developed a new method to create heat-resistant alloys that have flexible mechanical properties. Their breakthrough came after successfully managing the mechanical characteristics of high-entropy alloys, paving the way for a new era of material production.

The researchers behind this development are confident that their approach will revolutionize the creation of heat-resistant materials for aviation and power engineering. They believe that their method will open up new possibilities for the creation of alloys that can withstand extreme temperatures and stress, ultimately improving the safety and durability of critical parts and machinery.

The high-entropy alloys utilized in this new approach to alloy production contain five or more metal elements in equal or nearly equal atomic proportions. These alloys have been shown to possess excellent performance and mechanical properties, including corrosion and heat resistance. However, their flexibility has traditionally been a challenge, making them difficult to use in applications that require materials to bend or flex.

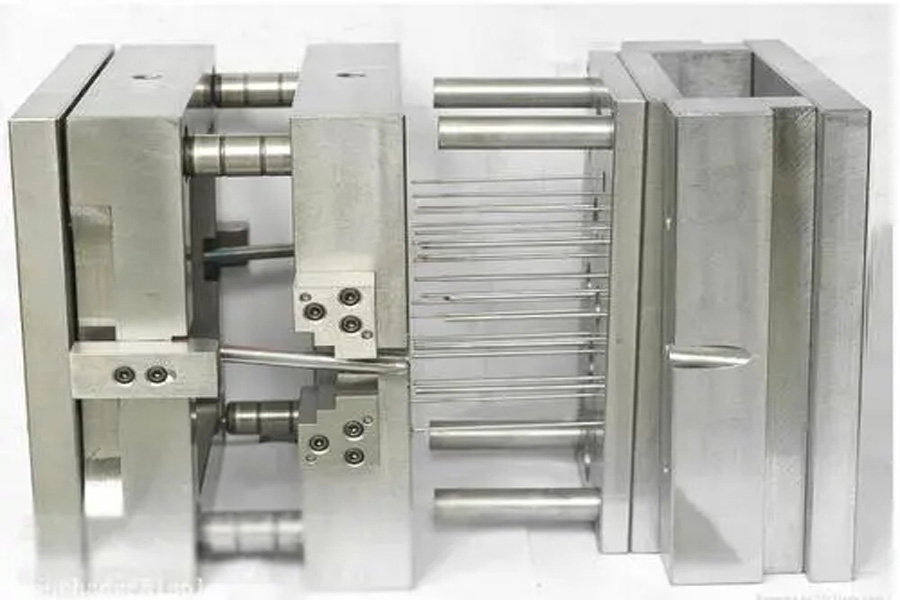

The researchers at BelSU have succeeded in controlling the mechanical properties of these alloys by customizing their microstructure. By creating a hybrid structure of nanocrystals and ultrafine-grained elements, they have produced an alloy with both strength and flexibility. This method has resulted in a material with a high yield strength and significant plastic deformation – characteristics that are crucial in engineering applications.

The new heat-resistant alloy created through this innovative production process is expected to be used in a range of applications, including turbine blades, exhaust systems, and other high-temperature components in aviation and power engineering. Its enhanced flexibility means that it can be formed into complex shapes and designs, improving the efficiency and safety of critical machinery in these industries.

This new approach to heat-resistant alloy production holds tremendous promise for the future of industrial and commercial processes. It demonstrates the potential for researchers to create new materials with superior mechanical properties and durability. The use of high-entropy alloys in heat-resistant material production is a significant development, and as further research is conducted, we can expect even more innovations in this field.

In addition to BelSU's breakthrough, leading companies worldwide are also investing in research and development of heat-resistant alloys. One industry giant that has made significant strides in this field is SHOUGANG Heat Resistant Alloy, a Chinese-based manufacturer that specializes in high-temperature alloys for advanced applications. The company has utilized advanced technology and production methods to create high-performance alloys that can withstand extreme temperatures and wear resistance.

In conclusion, the production of flexible heat-resistant alloys is a critical development in material science. The new method developed by BelSU scientists shows the potential to revolutionize the production of alloys that are essential in a wide range of industries. As the demand for high-performance alloys increases, we can expect further innovations in this field, including the use of high-entropy alloys and advanced production methods that will improve the durability and efficiency of industrial processes. Companies like SHOUGANG Heat Resistant Alloy are paving the way for further developments, and we can expect significant advances in material science in the years to come.