Copper nickel alloys are known for their exceptional seawater corrosion resistance and antifouling properties. These alloys are widely used in marine applications such as boat hulls, offshore sheathing, and other equipment that is exposed to seawater. In this blog, we will discuss the state of the art review of seawater corrosion resistance and antifouling of copper nickel (cupronickel) alloys.

Copper nickel alloys come in various compositions, such as 90-10 and 70-30 alloys. The 90-10 alloy contains 90% copper and 10% nickel, while the 70-30 alloy contains 70% copper and 30% nickel. Both these alloys have excellent seawater corrosion resistance and antifouling properties.

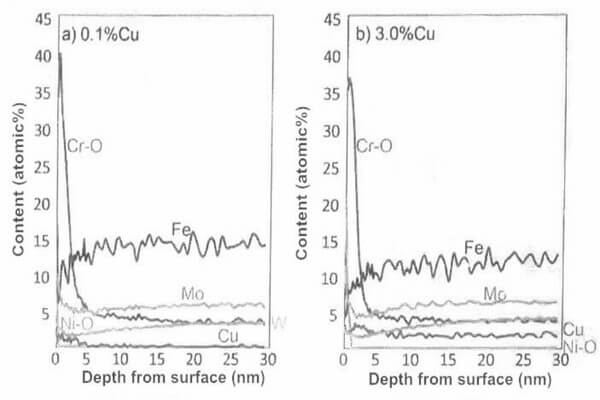

Surface Films:

Surface films are a layer of oxidation that forms on the surface of copper nickel alloys due to seawater exposure. These films provide excellent protection against corrosion and help in preventing biofouling. It is essential to maintain these surface films to ensure the longevity of copper nickel alloys.

Localized Corrosion:

Localized corrosion is the preferential attack of certain areas of copper nickel alloys. This type of corrosion is more prevalent in areas where the surface films are damaged or absent. It is essential to protect these areas from corrosion by using corrosion inhibitors or coatings.

Sand Erosion:

Sand erosion is another type of corrosion that occurs in high-velocity seawater. The erosion of sand particles can cause mechanical damage to the surface films and lead to corrosion. The use of coatings and cathodic protection can help to prevent sand erosion.

Galvanic Issues:

Galvanic issues occur when two dissimilar metals are in contact with each other in seawater. This type of contact can cause galvanic corrosion, leading to the deterioration of copper nickel alloys. It is essential to provide proper insulation or use cathodic protection to prevent galvanic issues.

Sulfides and Ferrous Sulfate Treatments:

Sulfides are harmful compounds that can cause severe corrosion to copper nickel alloys. Ferrous sulfate treatments are an effective way to remove sulfides from the surface of copper nickel alloys. This treatment involves the immersion of the alloy in a solution containing ferrous sulfate.

Biofouling:

Biofouling is the growth of marine organisms on the surface of copper nickel alloys. This type of fouling can cause significant damage and lead to corrosion. The use of coatings and biocides can help in preventing biofouling.

Boat Hulls and Offshore Sheathing:

Copper nickel alloys are widely used in the construction of boat hulls and offshore sheathing. These alloys provide excellent corrosion resistance and antifouling properties, making them a popular choice in marine applications.

In conclusion, copper nickel alloys offer excellent seawater corrosion resistance and antifouling properties. The use of proper maintenance techniques, coatings, and cathodic protection can help to ensure the longevity of these alloys in marine applications. The state of the art review of seawater corrosion resistance and antifouling of copper nickel alloys covered in this blog will help in understanding the importance of these alloys in marine applications.